Manufacturing within New Zealand - the case for RFID Technology.

ZenTag is actively working with Aluminium extrusion, framing and Glass manufacturing companies, most of those companies have purchased or are buying new plant to double their production capacity.

They have asked us to help them improve the traditional manual supply and support processes so their staff can keep up with the increased production.

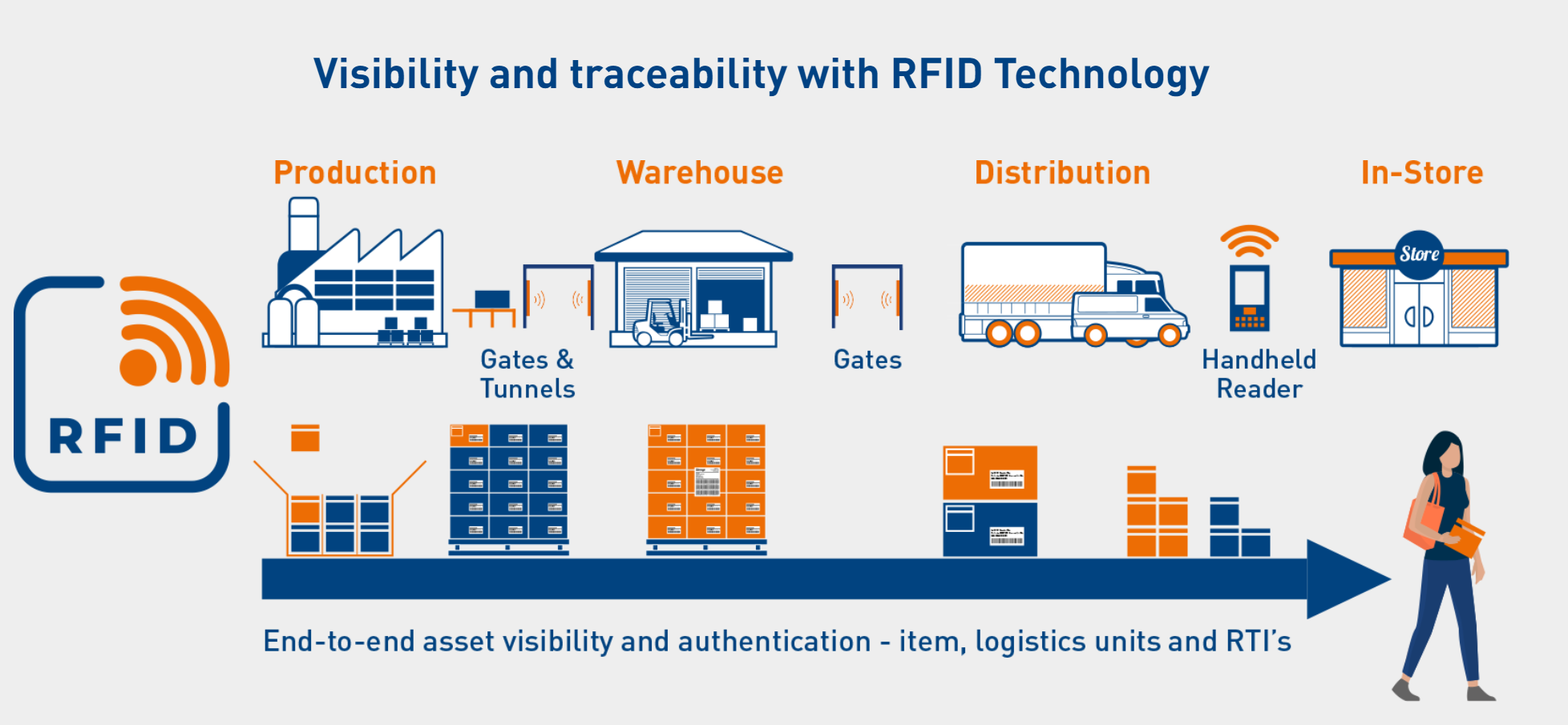

RFID Manufacturing technology enables better inventory control, production planning, quality control and defect recording/remediation.

But most importantly, it increases your workers efficiency and productivity. Staff love using RFID, they learn to trust the RFID generated inventory counts, work in progress information and identity of manufactured items. Staff soon realise that RFID Tagging items proves they made, shipped, received, or installed the right component.

ZenTag’s job has been made easier by a huge global growth in available Manufacturing RFID technology options,

As an example of this, we RFID tag precast concrete, injection moulded composite and aluminium items so that they can be easily identified for process, workflow, traceability, and compliance requirements.

We sell RFID Hardware in the form of sled readers that Bluetooth pair to any Smartphone, we can offer RFID Overhead readers that use Scanned Array Antenna like fighter jet Radar, to sweep scan a warehouse floor for RFID tagged items.

We commonly collect the RFID scanned data into RFID middleware e.g. The Idencia Blog | Product Tracking for Infrastructure which offers easy integration or upload into existing systems and is fast and efficient to setup and customisation.

RFID middleware like Idencia replaces all paperwork with smartphone data entry. Any process starts by RFID scanning the Items RFID tag, so you know you have the right item. Then you use the smartphone to add drawing photos, item defect photos, GPS location, onscreen signatures, and to complete smart processes which are synchronised up into the items record in the cloud. Where it can be viewed from any browser. RFID Middleware offers customised compliance reports and dashboards for real time visibility on what is happening on the manufacturing floor.

Lastly, implementation of RFID technology collects lots of data on your business, time stamped data for analyst so you can spot trends before they impact the business.

I can visit you to show you RFID working in your workplace and to discuss your requirements.

Thanks

Paul